The importance of wire tinning machine in electrical engineering

May 04, 2023|

May 04, 2023| View:168

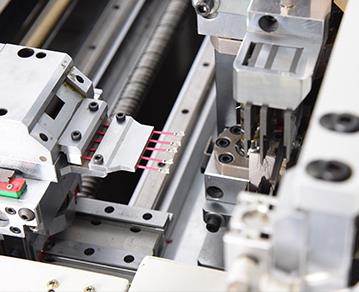

View:168Wire tinning machines are an important piece of equipment in modern electrical engineering. These machines play an important role in the production of high quality wire for various applications including power distribution, telecommunications and electronics. In this article, we will discuss the importance of wire tinning machines in electrical engineering.

Wire tinning machines are used to coat wires with a thin layer of tin or other metal alloys. This process, called tinning, has several advantages that make it an essential step in the production of electrical wire. Tinning improves the electrical conductivity, corrosion resistance and solderability of the wire, making it more durable and reliable.

The main advantages of tinning wire:

(1) Improved electrical conductivity.

Tinned wires have a lower contact resistance than bare wires, resulting in better electrical performance and reduced signal loss. This makes them ideal for high-speed data transmission and communication systems.

(2) Improved corrosion resistance.

Tin plating creates a protective layer on the wire surface that prevents oxidation and corrosion. This extends the life of the wire and reduces the likelihood of premature failure due to environmental factors.

(3) Improves the solderability of the wire.

The thin tin layer on the wire surface provides a good bonding surface for the solder, making it easier to join the wires together. This makes tinned wire ideal for use in electronic and electrical systems where components need to be joined quickly and efficiently.

There are several types of wire tinning machines, including hot air tinners, immersion tinners and laser tinners. Each type has its own unique advantages, depending on the application. However, all of these machines allow for precise control of the tinning process, thus ensuring consistent quality and minimizing waste.

In manufacturing, tinning machines play a critical role in producing high-quality wire that meets industry standards. Electrical engineers rely heavily on tinned wire for a variety of applications, from power and lighting to telecommunications. Without tinners, the manufacturing process would be slower, less efficient and more error-prone.

In addition, wire tinning machines are essential for the repair and maintenance of electrical systems. Tinned wire is easier to use and is ideal for replacing damaged or broken wire. This reduces downtime and ensures that critical systems are backed up and running in a timely manner.

In summary, tinning machines are essential equipment in modern electrical engineering. They play a vital role in producing high-quality wire that meets industry standards for electrical conductivity, corrosion resistance and solderability. Tin platers are used in a variety of applications, including power distribution, telecommunications and electronics. Without them, the manufacturing process would be slower, less efficient, and more prone to errors. Whether in production or maintenance, wire tinners play a critical role in ensuring the reliable operation of electrical systems. If you need more detailed information, feel free to contact us!

View More(Total0)Comment lists